TCB Metals and Refining

Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore .

WhatsApp)

WhatsApp)

Do you have value locked inside your ore concentrates? We can unlock that value and convert your ore into cash. TCB Metals and Refining, specializes in the recovery of precious metals from your ore .

Gold ore is a type of ore that can be obtained by mining gold ore rocks, requiring a Mining level of 40 or higher, and granting 65 experience. Gold ore can be smelted into gold bars through the Smithing skill, requiring level 40 Smithing. Gold bars can then be .

Gold, as it occurs in Nature, is never pure. Occasionally the amount of alloying metal is less than 1%, hut as a general rule it is greater; the commonest alloy, in fact, the invariable one, being composed of gold .

of highgrade ore per year for 8 years. The deposit contains ounces of gold per ton of highgrade ore and can be acquired at a cost of 10 per ton of ore (cost of mining ore at site). A sodium cyanide process is used to extract the gold from the ore, and various other processing techniques are used to produce % pure gold bullion from ...

A process routinely employed in the fire assaying of gold ores is the addition of silver prior to fusion of the ore in order to ensure that the silver content of the final bead is high enough to dissolve. This is called inquartation, and the separating of silver and gold by leaching with nitric acid is referred to as parting.

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in diameter, and on rare occasions ...

The hashing stage (corresponding to metal extraction and recovery stages) is a little more complex for gold ores, as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters, the gold mineralogical associations, and the gold particle size and liberation ...

Gold is processed by cyanide milling, a chemical procedure that separates 95 to 98 percent of the gold from raw mined ore. It is then refined to the gold standard purity, according to Mineweb. Heap leaching is a less expensive method of gold extraction, but it is a longer process and it recovers less gold than the cyanide milling process.

Apr 24, 2017· How to Use Bleach on Gold Ore to Remove Gold ... This is an exothermic process, meaning that the flask containing the acidandbleach mixture becomes very hot. Warnings. Perform the job outdoors or in a fume cupboard if possible, as chlorine is a toxic gas. References.

Many people who may have difficulty to identify the gold in the rock, because gold is usually often confused with the kind of carrier minerals pyrite, chalcopyrite, pyrhotite, pentlandit and goldcolored mica, because the mineral carrier is very similar to a vein of gold ore.

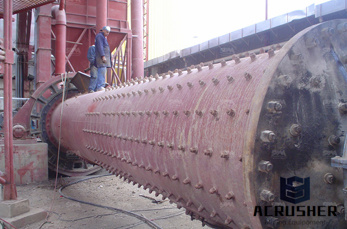

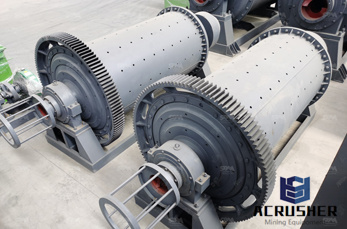

finetuned each step of the process from crushed ore to gold pellet. Their method is as follows: The first step after crushing the ore is milling. This takes place in metal drums with hard metal rods or balls. No mercury is added. After milling, the groundup ore is flushed into a sluice. There are a variety of sluices

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

Aug 06, 2015· We had a customer send us some very high grade gold quartz ore which we recovered troy ounces from only 300 lbs! We ran the quartz through our 1/21 ton per hour complete turnkey processor ...

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing completely updated edition features coverage of established, newly implemented ...

Gold Cyanide Solution (Leaching Gold With Cyanide) Since the 1890''s, cyanide has been used to recover gold from gold bearing ores. And today, over 115 years later, most of the worlds gold is recovered with cyanide playing a large part in the beneficiation of the yellow precious metal.

The addition of scrap iron to smelt mixes is a useful technique to smallscale operators experimenting with smelting techniques on goldsilver ores. It could also be used with small lots of sulfide concentrates. On the other hand, there are alternatives for processing sulfide ores.

Gold ore processing. In placer mines, the gold is recovered by gravity separation. For hard rock mining, other methods are usually used. Cyanide process. Cyanide extraction of gold may be used in areas where fine goldbearing rocks are found. ...

For extracting gold from lowgrade ores, heap leaching is practiced; huge heaps are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled ore, dissolving the gold. There are very well defined rules for the safe and responsible use of cyanide – as laid out in the International Cyanide Code. Gold refining

Gold is usually found alone or alloyed with mercury or silver, but can also be found in ores such as calaverite, sylvanite, nagyagite, petzite and krennerite. Most gold ore now comes from either open pit or underground mines. The ores sometimes contain as little as 5/100 of an ounce of gold .

Mineral Processing. If the mineralogy of the ore shows that you can separate discrete particles of the mineral you want from the gangue components of the ore, then it is possible to physically concentrate the valuable mineral and reject the rest. The easiest method for achieving this is by gravity separation.

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing operation. This completely updated edition ...

The lifecycle of a gold mine. People in hard hats working underground is what often comes to mind when thinking about how gold is mined. Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as ...

Each process relies on the initial grinding of the gold ore, and more than one process may be used on the same batch of gold ore. Mining 1 In lode or vein deposits, the gold is mixed with another mineral, often quartz, in a vein that has filled a split in the surrounding rocks. Gold is obtained from lode deposits by drilling, blasting, or ...

WhatsApp)

WhatsApp)