Used Hammer Mills and Bowl Mills | Wabash Power Equipment ...

Wabash Power is the largest supplier of refurbished Raymond bowl mills and hammer mills. Our shop in Saginaw, MI has a huge inventory of refurbished mills ready to ship.

WhatsApp)

WhatsApp)

Wabash Power is the largest supplier of refurbished Raymond bowl mills and hammer mills. Our shop in Saginaw, MI has a huge inventory of refurbished mills ready to ship.

2018 Hot Sale Talc Powder Grinding Roller Mill With Low Consumption, Find Complete Details about 2018 Hot Sale Talc Powder Grinding Roller Mill With Low Consumption,Grinding Roller Mill from Mine Mill Supplier or ManufacturerHenan Xingyang Mining Machinery Manufactory

Pakistan a mineral factory, heavy calcium carbonate powder . Pakistan a mineral factory, heavy calcium carbonate powder, 2 sets of Roller Mill Production Line. annual output 30000T, particle size D97:815μm Pakistan a mineral factory, heavy calcium carbonate powder, annual output 30000T, particle size D97:815μm, 2 sets of Roller Mill Production Line.

HCH1395 is the biggest ultra fine circleroll grinding mill in China. This HCH ultrafine grinding mill features in spacesaving, completeness, wide use, easy operation, smooth performance, high performancecost ratio and high efficiency. HCH Ultrafine Grinding Mill (Live Video)

Roller Mill Grinders Modern Process Equipment. principles of operation, there are four main advantages that direct people to use a roller mill rather than a hammer mill, ball mill, cone mills or some other. Get Price

Nov 22, 2017· Zhengzhou ShuGuang Heavy Machinery Co., Ltd. Telephone: / Call: Email:shuguang_ballmill Application range: dry ball mill is also known as dry mill. It is mainly used in powder grinding of finished products...

The Power consumption of Four Roller Mill(LRM1250) is 105 to 110 units per hour. [ The above production figures are on tentative basis as it depends upon the hardness Grinding ability of the mineral which may vary +/ ]

Nelson Machinery supplies used Raymond Roller Mills worldwide. Single Whizzer or Double Whizzer air classifiers are included with complete roller mill systems. Roller mills use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others.

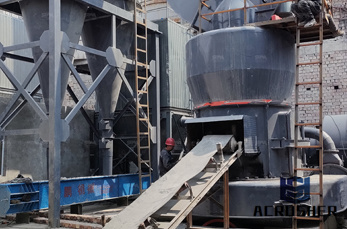

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics. It is an energy efficient alternative for a ball mill. Overview. Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal ...

mineral Grinding machine Introduction. Our variety of machines aim to provide the best solution for different minerals Pulveriser For high production, high mesh 100 350 mesh of mineral powder. 3 Roller MillFor high production, high mesh 100 350 mesh of mineral powder, with an advantage of low electrical Drive PulveriserFor higher mesh like 300 400 mesh production of ...

Jan 13, 2019· The purpose is to break the valuable mineral grains free of the gangue minerals, so that they can be physically separated from each other. This makes it possible to produce a pure mineral concentrate using processes like froth flotation or magneti...

raymond mill pulverizer 7 rows Raymond Mill is also called Raymond roller mill,raymond grinding mill,raymond pulverizer. YGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various nonflammable and nonexplosive mineral materials with Moh''s hardness less than and humidity less than 6%.

Mineral Vertical Roller Mill For Cement Grinding, Find Complete Details about Mineral Vertical Roller Mill For Cement Grinding,Vertical Mill,Vertical Roller Mill,Roller Mill from Mine Mill Supplier or ManufacturerHenan Heavy Industry Science Technology Co., Ltd.

SINGHASINI Manufacturer of Three / Five Roller Grinding Mill provide an automatic, dust free system for fine grinding of Soft to Hard Minerals up to 7 Moh''s Scale. Get Price And Support Online; 6 roller mill for grinding of asphalt hotelcrystalinn. Three/Five Roller Mill for Mineral/Ore Grinding. 3 / 5 Roller Mill for Mineral / Ore Grinding.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Crushers, Pulverizers, Grinders Knife Mill Blender Pulverisette 11 Knife Mill Blender Pulverisette 11 The Knife Mill Homogenizer Pulverisette 11 is the ideal Laboratory Mixer for fast size reduction and homogenization of Food samples. Quantity. Add to Quote request. Quick View

This innovative Loesche industrial mineral mill stands out for its: • Simplified and robust mill construction • Fast assembly of mill and classifier thanks to preassembled components • Complete preassembly of smaller mills • Maintenance friendly thanks to ease of access and use of high quality materials

Used Roller (Mill) Equipment. Roller mills can be either vertical or horizontal and are referred to a refiners or finishers. The applications all require passing the material both dry as well as wet products through the rollers which are gapped at the nip point for precise size reduction.

Vertical Roller Mill. Vertical roller mill as a kind of high efficiency and energy saving equipment, its technical characteristics is single large production capacity, low energy consumption per unit of product, product size distribution narrow, purity, good fluidity, vertical milling machine as a kind of superfine grinding equipment. READ MORE

Nov 24, 2017· Ring roller mill has widely application in the field of slag, coal mine, cement, nonmetallic mineral and other industries, Fujian Fengli produced ring roller mill has many advantages and.

HPGR or highpressure grinding rolls have made broad advances into nonferrous metal mining. The technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent years. After these developments, an HPGR based circuit configuration would often be the base case for certain ore types, such as very hard, abrasive ores.

Loesche in Düsseldorf received a followup contract for a coal mill, of the type LM D, which is the same type of coal mill already successfully deployed by RWE Power AG in Niederaußem. In July 2012, RWE Power in Essen commissioned a new vertical roller mill from Loesche (Fig.).

Jul 03, 2019· In the ground calcium carbonate roller mill, there are often several tiers of rollers, which, when activated, will squeeze and rub the feed limestone to calcium carbonate powder. And the roller mill can produce mesh of ground calcium carbonate powder with low energy consumption.

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy efficient alternative for a ball mill power consumption of roller mill for raw material CEMENT INTERNATIONAL134 Мб. Get Price

WhatsApp)

WhatsApp)