Cement from CO2: A Concrete Cure for Global Warming ...

Aug 07, 2008· The Calera process essentially mimics marine cement, which is produced by coral when making their shells and reefs, taking the calcium and magnesium in seawater and .

WhatsApp)

WhatsApp)

Aug 07, 2008· The Calera process essentially mimics marine cement, which is produced by coral when making their shells and reefs, taking the calcium and magnesium in seawater and .

Improve Of Cement Making Process; Improve Of Cement Making Process. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. And they are mainly used to crush coarse minerals like ...

Dec 31, 2008· The Guardian Back to home. ... if Novacem can make their cement at a competitive price, the next step could be to take even more CO2 emissions out of the process .

Concrete production is the process of mixing together the various ingredients—water, aggregate, cement, and any additives—to produce concrete. Concrete production is timesensitive. Once the ingredients are mixed, workers must put the concrete in place before it hardens.

Cement, in general, adhesive substances of all kinds, but, in a narrower sense, the binding materials used in building and civil engineering construction. Cements of this kind are finely ground powders that, when mixed with water, set to a hard and hardening result from hydration, which is a chemical combination of the cement compounds with water that yields submicroscopic ...

The tips below will acquaint those new to concrete with the process. Once you have read this information, you should be ready to launch DIY projects such as making concrete garden stepping stones. How to Mix Concrete: Getting the Consistency Right .

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Oct 12, 2019· How to Pour Exposed Aggregate Concrete. This article is helpful to anybody who wants to pour exposed aggregate concrete at home or for commercial use. It will explain the proper procedure and list all the necessary materials. This...

Aug 29, 2018· To make their concrete, Romans used much less lime, and made it from limestone baked at 900 degrees Celsius (1,652 degrees Frenheit) or lower, a process .

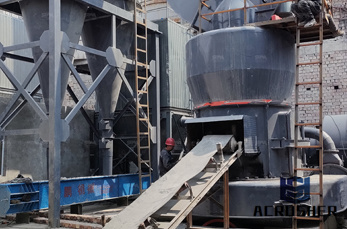

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Accurate cement production also depends on belt scale systems to monitor output and inventory or regulate product loadout, as well as tramp metal detectors to protect equipment and keep the operation running smoothly. The Cement Manufacturing Process flow chart sums up where in the process each type of technology is making a difference. NOTE:

Mar 19, 2015· What Happened to Green Concrete? ... which releases carbon when it is heated during the cementmaking process. ... The solids formed in this process can improve the material''s strength by .

When natural carbonation is combined with measures to decarbonize or improve the energy efficiency of cementmaking, as well as technologies to capture CO2 emitted during cement manufacturing, it can result in a net atmospheric CO2 reduction. Policies to reduce CO2 from cementmaking

Concrete curing and concrete drying are different processes. Concrete curing is the process of hardening that begins immediately after the concrete is poured. A majority of the concrete curing process is completed after 28 days although concrete hardening continues for a .

Sep 23, 2015· During manufacture the cement particles are given a chemical coating which imparts water repelling property where by the cement is not affected by high humidity and hence be stored without deterioration for a longer period. Low Heat Portland cement (LHC) (IS12600). Used for making concrete for dams and other water retaining structures, bridge ...

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making An ENERGY STAR® Guide for Energy and Plant Managers August 2013 ENERGY STAR is a Environmental Protection Agency Program helping organizations and individuals fight climate change through superior energy efficiency. Document Number 430R13009

Apr 13, 2016· The process of creating cement emits upwards of 80 percent of the cement''s weight in carbon dioxide and accounts for about 5 percent of humangenerated CO2 emissions annually. Though the white block''s production still requires some of the CO2emitting fuel use of typical cement making, CO2 is also one of the ingredients used to create it.

Although there are other cements for special purposes, this module will focus solely on portland cement and its properties. The production of portland cement begins with the quarrying of limestone, CaCO3. Huge crushers break the blasted limestone into small pieces. The crushed limestone is then mixed with clay(or shale), sand, and iron ore and ground together to form a homogeneous powder ...

Nov 15, 2007· Cement making process. I don''t owe any copyrights for this video. I just uploaded it because there was no good video about cement making process at that time.

Mar 03, 2016· Making concrete green: reinventing the world''s most used synthetic material ... and the subsequent chemical process of turning limestone into small rocks of cement .

Slump and Concrete Strength of Air Entrained Concrete. During the making of concrete a slump test is mandatory and normally slumps of about 3 inches are used for good workability. However when air entraining agents are used, the slump can reduce to between 1 to 2 inches while still having the same desired workability.

Cement hydration. By the process of hydration (reaction with water) Portland cement mixed with sand, gravel and water produces the synthetic rock we call concrete. Concrete is as essential a part of the modern world as are electricity or computers. Other pages on this web site describe how PC is .

Making Concrete: Gradually wet the mix. Family Handyman. Pull a small amount of the dry mix into the water with a hoe and mix it completely. A hoe makes a great mixing tool. A flat shovel or spade works too. Continue pulling and mixing until all of the powder is wetted and the mix is .

WhatsApp)

WhatsApp)