Hammermills International – Industrial Shredders and Metal ...

Hammermills International provides metal recycling machinery and industrial shredders to assist in scrap metal to mass automobile recycling.

WhatsApp)

WhatsApp)

Hammermills International provides metal recycling machinery and industrial shredders to assist in scrap metal to mass automobile recycling.

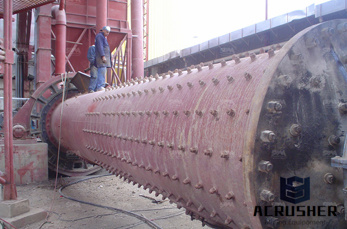

SHREDDERS. Hammermills International is the exclusive licensed manufacturer of Metpro Hammermill shredder design! The"Hammermills/METPRO" Shredder is able to shred heavier mixed grades of material efficiently, to a high quality, at a low cost and with a high recovery of nonferrous material.

/ Shredders and Hammer Mills Shredders deal with a wide variety of waste materials including ferrous metal, aluminium, cables, plastic, wood, paper and computer hard drives. JMC McIntyre supplies scrap shredders for every type of application, whether it''s in your factory, laboratory or outside in your yard.

Get the best deals on Hammer Mills when you shop the largest online selection at Free shipping on many items | Browse your favorite brands | affordable prices. Skip to main content. Shop by category. Shop by category. Enter your search keyword

Mobile and stationary hammer mill shredders with complete downstream solutions. We see the future of scrap processing differently and believe the processing power is shifting to the small yards. Our sole focus is to arm small scrap yards with affordable, hammer mill processing and sorting solutions.

Main products: wood chipper,Scrap Metal Hammer Mill Shredder, Shaft Shredder,biomass grinder,Hammer Mill, Chaff Cutter,Wood products are widely used for the forestry, waste recycling, biomass,agricultural and wooden boards markets.

*Note: Prices shown are suggested retail and do not include freight, dealer set up, or applicable local taxes in US Dollars. Prices and specifications are subject to change as new developments and improvements are made.

Metal Hammer Mill Shredder: We deliver scrap metal hammer mill shredders starting from 280KW right up to 4,500KW that offer world leading performance and reliability at industry leading low operating costs.. Shredwell metal hammer mill shredders are widely used as primary shredder or secondary shredder in metal recycling industry to produce a high quality density metal fraction.

Hammer Mill Working Principle The hammermill, fundamentally, is a simple mechanism. The "orthodox" machine comprises a boxlike frame, or housing, a centrally disposed, horizontalshaft rotating element (rotor) on which the hammers are mounted, and usually a set of circumferentially arranged grates in the lower part of the housing.

The hammermill can be used as a primary, secondary, or tertiary crusher. Small grain hammermills can be operated on current. Large hammer mills used in automobile shredders may be driven by diesel or electric motors ranging from 2000 to over 5000 horsepower ( ).

May 11, 2015· The Saturn Hammermill product line is ideal for nonferrous metal scrap recycling. From its early days under the Magnatech brand, the Hammermill line has been known for its durability and reliability.

Used, unused and refurbished hammer mills for a fraction of the cost of new. USbased Phoenix Equipment is a global buyer seller of hammer mills and other industrial equipment. Review our vast inventory or talk to our team today.

: AmazonBasics 12Sheet CrossCut Paper and Credit Card Home Office Shredder Hammermill Paper, Copy Paper, x 11 Paper, 20lb Paper, 92 Bright, 8 Ream Case / 4,000 Sheets Acid Free Paper: Electronics

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes.

High speed, high volume hammermills with 20,000 fpm hammer tip speed for high capacity grinding to a small particle size. Features a large diameter hammer circle and throat widths from 20" to 60". These rugged mills have near full circle sizing screens to maximize production and .

Rotary Shear Hammer Mill Shredders. Founded in 1998, Zato designs and manufactures machinery and systems for processing and recycling scrap metal: TwinShaft Shear type Shredders Hammermill Shredders for Ferrous and NonFerrous processing.

Hammer Shredder : Hammer Type Metal Recycling Machine. Shredwell HS series Hammer Shredder is the main metal recycling machine in scrap metal recycle industry,it is aggressively size reduce and densify preshredded material whilst liberating the various different fractions and allowing for better separations and reduced transport costs.

WENDT CORPORATION''s automobile shredders are designed to offer reduced energy consumption while producing clean, highdensity scrap at optimum tonnages. WENDT''s H EAVY hammermill shredders are designed to be the most durable, efficient, reliable, and serviceable automobile shredder in .

Remote controls used to fully open the shredder and enable maintenance operations in a unique way, make it the best shredder by far. Pin puller is a specially designed hydraulic mechanism to facilitate the installation and removal of rotor hammer pins. It is integrated in a mobile maintenance platform

As hammer design depends upon the type of work done by the crusher, American hammers are skillfully designed to contribute the greatest efficiency to achieving customers'' requirements. Hammer material can be cast or forged manganese, cast alloy steel, cast white iron, or fabricated from high alloy plate (360–500 Brinell).

In all, Bonfiglioli drake hammer mill shredders are easy to maintain and cost less to run than their competitors, whilst producing a high quality density shred. And there are no hidden costs, if you purchase a Bonfiglioli hammer mill shredder the price includes warranty, set .

Hammel VB 650 D ES Shredder Serial Number: 11035 1998 Model 3000 Hours (Approx.) Basic Hammel Specifications Hook Lift Cummins Diesel Engine 330 HP 5/7/7 Rotors Side Cones Breaker Bar 37,400 Pounds Extended Conveyor with New Belt for Hammer Mill in Feed

EScrap Hammer Mills Shredders. The dual stage EDestroyer Hammer Mill offers superfine electronic scrap grinding, under 2MM, at very high production rates. The energy resulting from the dual revolving rotors produces a suspension zone that provides additional size reduction. As a result, a finer grind is achieved in one pass through the mill.

The design structure of the any Hammer mill system is always determined by the end use. All CM models are custom configured to suit the user''s material and production goals. CM Hammer mills are available in more than 20 sizes, ranging from 6" to 72" in and in multiple horsepower options from from 2 .

WhatsApp)

WhatsApp)