Mineral and Mining Engineering: How does a silica sand ...

Jan 01, 2014· This video may can help you. https:// In the silica sand production line, Jaw Crusher is the coarse silica sand crushing machine ...

WhatsApp)

WhatsApp)

Jan 01, 2014· This video may can help you. https:// In the silica sand production line, Jaw Crusher is the coarse silica sand crushing machine ...

May 10, 2016· Frac sand mining is the mining of sand that is used in the fracking process to get oil and natural gas out of the ground.

Industrial sand mining overview. Sand mining has occurred in Wisconsin for more than 100 years. Recent growth in the petroleum industry has created a high demand for sand that can be used for hydraulic fracturing, a technique used to extract natural gas and crude oil from rock formations in .

Nov 13, 2018· Sand mining is the process of extracting sand from an open pit, sea beaches, rivers and ocean beds, river banks, deltas, or inland dunes. The extracted sand can be used for various types of manufacturing, such as concrete used in the construction of .

Sand and Gravel Mining Process. ... according to the industry''s own estimates, by working with the Partnership, the sand and gravel mining industry has generated well over 2,000,000 in additional revenue. Lake Shore Housing Developments . When outofproduction mines are prepared for real estate development, the remaining sand is formed into ...

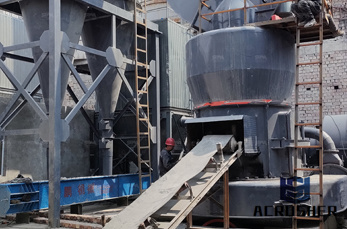

silica sand mining process] Production Line manufacturer in Shanghai, China. silica sand mining process] Production Line is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions.. XSM stone crushing machine projectsilica sand mining process] Production Line

SAND AND SAND MINING Part I. Source: Unknown Uses of sand This resource is sand, not sand and gravel. Its primary source is sand dunes, therefore Michigan ranks third in the US in industrial sand production. Silica sand is the major component of glass, foundry molds, and abrasives. It is also used in ceramics, on golf courses, and as a filter ...

CASE STUDIES OF ENVIRONMENTAL IMPACTS OF SAND MINING AND GRAVEL EXTRACTION FOR URBAN DEVELOPMENT IN GABORONE by TARIRO MADYISE submitted in accordance with the requirements for the degree of MASTER OF SCIENCE in the subject ENVIRONMENTAL MANAGEMENT at the UNIVERSITY OF SOUTH AFRICA SUPERVISOR: PROF MOJA .

silica sand minig process schutsluisalblasserdamnl. Sand mining WikipediaSilica sand mining business has more than doubled since 2009 because of the need for this particular type of sand, which is used in a pro. Silica Sand Mining Process] Production Line

Metallurgical ContentThe Silica Sand FlowsheetSANDSTONE DEPOSITSOPEN SAND PIT (Dry)OPEN SAND PIT (Wet)PRIMARY CLASSIFICATIONATTRITION SCRUBBINGSECONDARY CLASSIFICATIONCONDITIONING AND FLOTATIONFINAL DESLIMINGDRYING AND DRY GRINDINGSummary of the Silica Sand Processing Plant EquipmentA Flowsheet for Beneficiation of .

The more expensive the extraction process the greater the cost that must be passed on to the consumer of the final product. Included in the cost of mining are blasting, removal of overlying rock and soil (overburden), mechanization, and reclamation of the mined area. The last major consideration of the sand mining industry is ore processing ...

May 12, 2014· The Manufacturing Process. Rocks or quarry stones are blasted and subjected to a series of crushing cycles to reduce the particles to the size of naturally occurring sand. The produced sand is then sieved and washed to remove fine particles and impurities, and tested for various quality aspects before it is deemed fit as a construction aggregate.

The Manufacturing Process Processing rock salt 1 Underground salt deposits are usually discovered by prospectors searching for water or oil. When salt is detected, a diamondtipped, hollow drill is used to take several regularly spaced core samples throughout the area.

With years of process team knowledge, McLanan is the most experienced manufacturer of wet processing plants for frac sand production in North America. The company has a solution for all stages of the frac sand process, including crushing, screening, washing and classifying, and dewatering, as well as fines recovery, sampling and water management.

Sand mining is the extraction of sand, mainly through an open pit but sometimes mined from beaches and inland dunes or dredged from ocean and river is often used in manufacturing, for example as an abrasive or in is also used on icy and snowy roads usually mixed with salt, to lower the melting point temperature, on the road can replace eroded coastline.

The demand for frac sand has exploded in the past several years as thousands of oil and natural gas wells are being stimulated using the hydraulic fracturing process. (See the production chart.) A hydraulic fracturing job on one well can require a few thousand tons of sand.

Introduction. Sand and gravel are used extensively in construction. In the preparation of concrete, for each tonne of cement, the building industry needs about six to seven times more tonnes of sand and gravel (USGS, 2013b). Thus, the world''s use of aggregates for concrete can be estimated at billion to billion tonnes a year for 2012 alone.

Oil sands, tar sands, crude bitumen, or more technically bituminous sands, are a type of unconventional petroleum sands are either loose sands or partially consolidated sandstone containing a naturally occurring mixture of sand, clay, and water, saturated with a dense and extremely viscous form of petroleum technically referred to as bitumen (or colloquially as tar due to its ...

manufacturing process of sandmining middelaartentverhuur. manufacturing process of sandmining, manufacturing process of sand mining,, robosand manufacturing process robo sand machinery and plant nldcindiain Sand mining Wikipedia Sand mining is a practice that is used to extract, It is often used in manufacturing as an abrasive,, which is used in a process,

The excavator and trucks are used prior to the start of the manufacturing process and are taxable, but the frontend loader, which carries the materials from the stockpile to the first work point, is used within the scope of manufacturing and qualifies for exemption if it is used exclusively for this purpose.

Manufacturing Process Of Sandmining. Calcite Deep Processing Plant in Belgium. Calcite deep processing production line in Belgium is composed of PE250×400 jaw crusher, electrovibrating feeder, HXM1021 micro powder mill, hoister, electrical cabinet, packing machine and pulse dust collector.

Frac Sand Plants. Frac sand is a form of proppant for the fracking process used in the oil and gas industry. The proppant''s basic function is to create and maintain the deepunderground passageways needed to harvest either natural gas or crude oil.

Oct 01, 2012· silica sand manufacturing process: ... Quartz Sand Mining Techniques | Quartz Stone ... This page is provide professional silica sand manufacturing process information for you, we have livechat to ...

The reclamation process begins as soon as mining operations are completed. In Situ. Using techniques that are similar to conventional oil production, we inject steam into the reservoir to heat the bitumen so it can be pumped to the surface. Suncor extracts and upgrades bitumen using the following process:

WhatsApp)

WhatsApp)