Cement Ball Mill manufacturers suppliers

China Cement Ball Mill manufacturers Select 2020 high quality Cement Ball Mill products in best price from certified Chinese Cement Mixer manufacturers, Ball Mill suppliers, wholesalers and factory on

WhatsApp)

WhatsApp)

China Cement Ball Mill manufacturers Select 2020 high quality Cement Ball Mill products in best price from certified Chinese Cement Mixer manufacturers, Ball Mill suppliers, wholesalers and factory on

May 08, 2015· 1212 Ball Mill Inspection Pinion #1 Inspection door Note gap where incorrect hinges have been welded onto door leaving void for dirt ingress. Urgent attention required! 13. 1313 Ball Mill Inspection LE fitted special PTFE seal tape to inspection doors. 14. 1414 Ball Mill Inspection Pinion #2 Inspection Door 15.

Mill Liners Minerals. secondary, and regrind ball and rod mills. Using a holistic approach, ... ® mill liners for exceptional life and reliability in the most ... for ball and SAG mill applications, specifically in areas such as grates ..... cal testing procedures, ensure .

Objective ball mill audits can help cement producers achieve 510% productivity gains. ... What to expect from a cement ball mill inspection; What to expect from a cement ball mill inspection. Share. May 02, 2019. by GCP Applied Technologies

Mining and Cement use ball mill balls forged ball and cast ball grinding media balls As a leading global manufacturer of grinding media, we offer advanced, reasonable solutions for any sizereduction ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** ... A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been ... During the inspection, mill and separator internal condition found in good condition and no

breakage on one of their ball mill heads. The breakage originated from the trunnion to head connection and worsened with time. conducted an inspection of the mill and recommended replacing the mill head rather than continue to suffer downtime and lost production. Results: manufactured the replacement head,

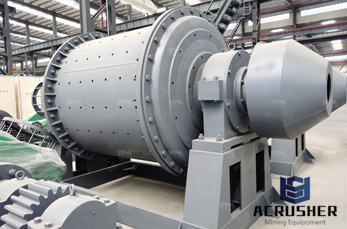

Ball Mill. We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

As a kind of grinding ball mill equipment, widely used in the processing of fluorite ore, limestone, iron ore, fly ash, gypsum, quartz, cement and other minerals, used in ore dressing process without ball mill, ball mill and classifier, crusher, magnetic separator, flotation machine, such as equipment of corresponding use, jointly promote the application of mineral aggregate mill ...

We are engaged in manufacturing and supplying ball mill, close circuits ball mill, open circuits ball mill, girth gear ball mill, ball mill for cement grinding, pinion drive ball mill, central drive ball mill, integral drive ball mill, slide shoe bearing ball mill, trunnion bearing ball mill. We are the best ball mill suppliers and manufacturers of ball mill, close circuits ball mill, open ...

Jul 05, 2008· Mine Safety and Health Administration Ball Mill Safety DVD573 1998 Developed cooperatively by MSHA and Lehigh Portland Cement Company. Outlines the various steps precautions and procedures ...

This ball mill is widely used in production lines for powders such as cement, silicates, new building materials, refractory material, fertilizers, glassceramics, etc.

CHAENG ball mill end cover adopts highstrength steel, and its structure is optimized by professional engineers according to the operation characteristics of ball mill, to greatly ensure the longterm operation stability and prolong the long service life.

We are engaged in manufacturing and supplying ball mill, close circuits ball mill, open ... ball mill, girth gear ball mill, ball mill for cement grinding, pinion drive ball mill, ... Oil housing with inspection door and proper sealing to avoid leakages...

OptiTromp Separators for Ball Mills High efficiency separators for bulk materials . From high efficiency separators in their OptiTromp family through to the allinone aggregate Heyd Separator on to the JS Classifier, which was developed especially for the high demands of the minerals industry: Christian Pfeiffer offers you a variety of separators to meet the special demands of your production ...

Cement Mill,Cement Mills,Cement Ball Mill,Cement Grinding . In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of raw material mill, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder.

Great Wall Steel Casting''s girth gears are applied in rotary kiln and ball mill for Turkey Tracim cement company,besides, we have many other cases as follows: Xinjiang Tianshan Building Material Group ordering 23t girth gear for rotary kiln. Henan Mengdian Group ordering 15t girth gear for cement ball mill.

inspection doors ball mills cement. This page is provide professional inspection doors ball mills cement information for you, we have livechat to answer you inspection doors ball mills cement .

Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and .

Haoyang steel balls manufacturing plant was put into operation in June, we deal with continuously growing consumer requirements for operational properties of grinding media, what directly affects ball mill prices and quality, efficiency of equipment and the enterprise in general.

After the ball mill is installed and has passed the inspection, it can run the test run should be responsible for the skilled operators, and strictly abide by the test operation rules of the ball mill, the following describes the operation of the ball mill test. First of all, the ball mill should be empty load test, its empty load test continuous running time is not less than 1224 ...

vertical mill / ball / for cement / miscellaneous waste FCB Horomill ... Inspection door and loaded with grinding media. Equipped with reducers and with toothed transmission. Compare this product. ball mill / horizontal / glass / for powders 8000M/D. Make a request. ball mill.

VDZ provides maintenance of cement plants for the cement industry. In addition, VDZ offers its maintenance services to all industries using rotary equipment. ... It requires regular, accurate and reliable inspections and surveys of rotary kilns and ball mills the core of any plant. ... Inspection of girth gear and pinion lubrication, function ...

WhatsApp)

WhatsApp)